AS Level Physics 9702

6. Deformation of solids

Written by: Adhulan Rajkamal

Formatted by: Adhulan Rajkamal

Index

6.1 Stress and strain

- Deformation is caused by tensile or compressive forces:

- Tensile → Causes extension

- Compressive → Causes compression

- Load → The external force applied to a material, causing it to deform; measured in newtons (N)

- Weight of the load on a spring → tensile force acting on the spring

- Extension → The increase in length of a material when subjected to a tensile load

- \( \text{Extension} = \text{Stretched Length} – \text{Original Length} \)

- Compression → The decrease in length of a material when subjected to a compressive load (pushing force)

- Hooke’s Law → Provided that the limit of proportionality is not exceeded, the extension of an object is proportional to the applied load

- The law can be expressed as: \( F \propto e \)

- Introducing a constant: \( F = k e \)

- \( k \) is the spring constant, defined as force per unit extension: \( k = \frac{F}{e} \)

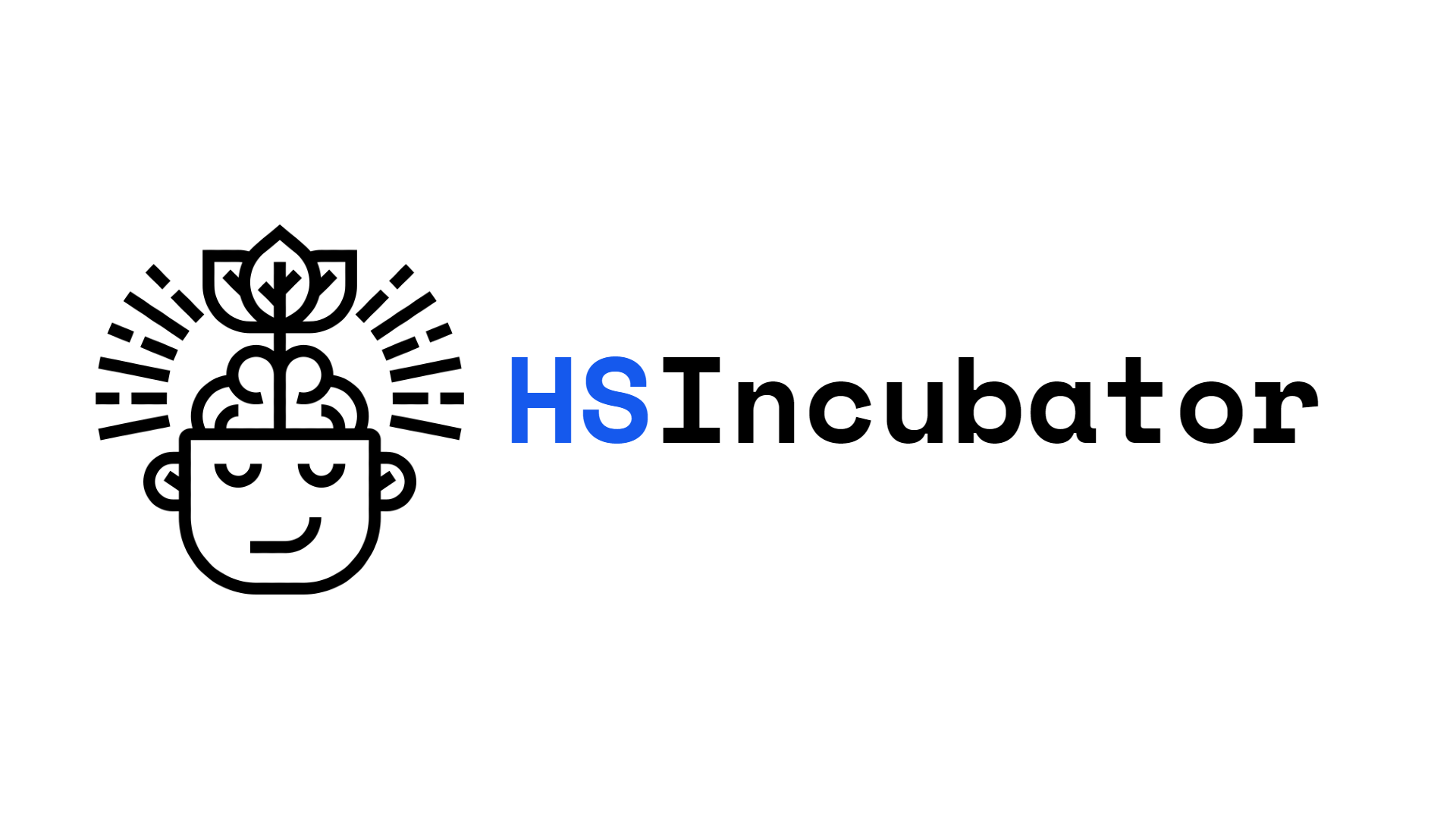

- Limit of proportionality → The maximum point up to which the material obeys Hooke’s Law; beyond this point, deformation becomes non-linear

The Young Modulus

- Stress (\( \sigma \)) → The force applied per unit cross-sectional area; measured in pascals (Pa):

\[ \sigma = \frac{F}{A} \]

- F → Force applied (N)

- A → Cross-sectional area (m²)

- Strain (\( \varepsilon \)) → The ratio of extension (or compression) to the original length of a material:

\[ \varepsilon = \frac{e}{L_0} \]

- e → Extension or compression (m)

- L₀ → Original length (m)

- Strain has no units

- Young Modulus (\( E \)) → A measure of the stiffness of a material, defined as the ratio of stress to strain within the proportionality limit

- In the region where the changes are proportional, it can be seen that:

- \(\text{stress} \propto \text{strain}\)

- Adding a constant to remove the proportionality sign: \[ \text{stress} = E \times \text{strain}\]

- The constant \(E\) is known as the Young modulus of the material.

- Rearranging the equation above gives the equation for calculating Young modulus:

\[

E = \frac{\sigma}{\varepsilon} = \frac{F/A}{e/L_0} = \frac{F L_0}{e A}

\]

- Measured in pascals (Pa) → Same unit as stress (\(\sigma\))

- Higher \(E\) indicates a stiffer material

Experiment – Young modulus

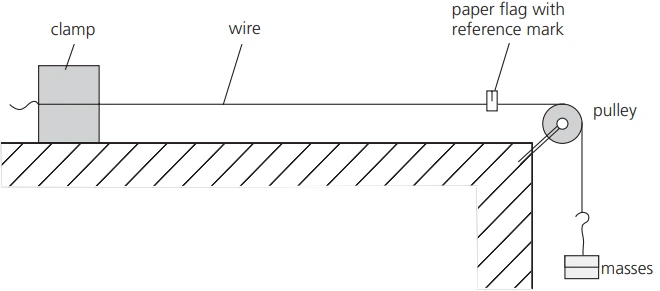

- The following setup can be used to perform a simple experiment to measure the Young modulus of a wire.

-

- Set-up: A wire is clamped at one end with a load carrier attached to the other; a paper flag marks the reference point.

- Measurements:

- Original length (\( L_0 \)) is measured from the clamp to the reference point.

- Diameter (\( d \)) is measured using a micrometer, and the cross-sectional area is calculated as: \[ A = \frac{1}{4} \pi d^2 \]

- Extension (\( e \)) is measured as masses (\( m \)) are added to the carrier.

- Calculation:

- Load (\( F \)) is found using: \[ F = mg \]

- A graph of \( F \) (y-axis) against \( e \) (x-axis) is plotted (Force-extension graph).

- The Young modulus (\( E \)) is determined from the gradient (\( \frac{F}{e} \)) as: \[ E = \frac{F L_0}{e A} = \frac{F}{e} \times \frac{L_0}{A} = \textit{gradient} \times \frac{L_0}{A} \]

- Note: Ensure the wire does not exceed the limit of proportionality for valid results.

6.2 Elastic and plastic behaviour

- Elastic limit → maximum stress or force that a material can withstand and still return to its original shape and size when the load is removed

- Elastic deformation → Object returns to its original shape and size when the force on it is removed; occurs within elastic limit

- Plastic deformation → Object does not return to its original shape and size when force is removed; occurs when the material is stressed beyond the elastic limit

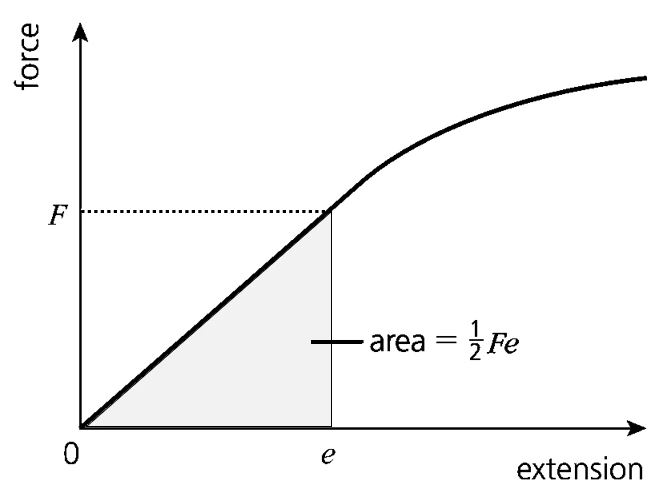

- Area under force-extension graph represents the work done

- Elastic potential energy of a deformed material = work done to deform the material (within its limit of proportionality)

- Equations to calculate the elastic potential energy of a deformed material:

-

\(

E_p = \frac{1}{2} F e

\)

→ Related to the area under the force-extension graph.

- \( F \) → Force

- \( e \) → Extension

-

\(

E_p = \frac{1}{2} k e^2

\)

Where:- \( k \) → Spring constant

- \( e \) → Extension

-

\(

E_p = \frac{1}{2} F e

\)

→ Related to the area under the force-extension graph.

- Derivation of the second equation:

- From the first equation: \( E_p = \frac{1}{2} F e \) and Hooke’s Law: \( F = k e \)

- Substituting \( F = k e \) into the first equation:

\( E_p = \frac{1}{2} (k e) e = \frac{1}{2} k e^2 \)